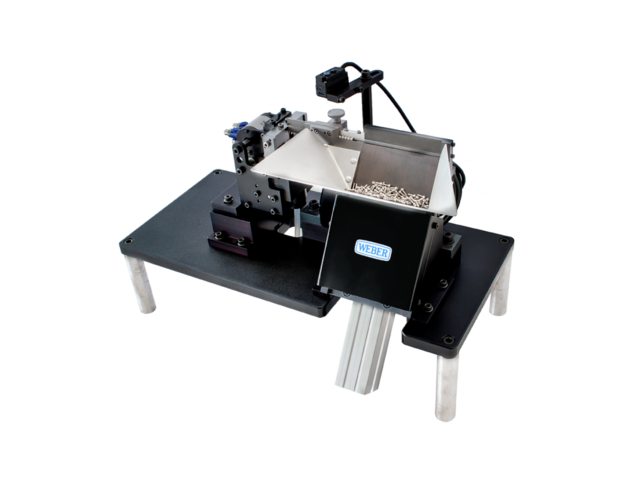

WEBER Mini Piezo Step Feeder ZEP120

Our latest model in our next generation of screw feeding technology using Piezo crystals and our proven step feeding technology. The new Mini Piezo Step range accommodates small and micro sized fasteners and gently pre-sorts the fastener orientation prior to allowing them to load into a buffer, ready for escapement and delivery. The Piezo unit is extremely quiet and compact in footprint making it an excellent choice for workplaces with high value real estate around the assembly process areas. The noise levels are extremely low producing, only 64dB, and high frequency vibration which is much less aggressive than 60Hz or 120Hz coil devices inflicting significantly less abrasion and damage to fasteners and their finish.

What makes these different:

This new mini step feeder utilizes Piezo crystal inlines that are controlled by applying a voltage across a set of Piezo crystals which oscillate in reaction to this voltage. The crystals and angular flat springs perform the conversion into a linear motion. This vibration does away with the old electromagnetic coils which required tuning and tighter controls to get that sweet spot which allowed vibration to be transferred into the parts being fed. There was also the issue of heat generation and electromagnetic field generation which sometime could be problematic. This product uses a single piezo crystal which results in a non-magnetic, light weight, high performance and extremely controllable feed mechanism. Frequencies can range from 140 to 400hz range and lends itself to smaller light mass fasteners and parts. This technology offers very high feed rates and it has become much easier to offer aligned screws, pins, studs and other small parts to be delivered in the correct orientation for the customers’ demands.